Almost all the manufacturing facilities are equipped with conveyors, as they are considered as one of the most important parts of an operation. Therefore, an organization needs to keep conveyors in top condition so that it works efficiently and does not suffer from an unexpected breakdown.

If a breakdown occurs you will not be able to afford downtime because this equipment is necessary for your core business. Hence, conveyor maintenance is a necessity.

What Is the Conveyor System?

The conveyor system is most frequently used in material handling and packaging industries. Their basic function is to move heavy material from one level to another. If human power is used for the same work then it will be costly and time-consuming as well. They can carry & move wight of all shapes and sizes.

Moreover, many conveyor systems have an inbuilt safety feature to avoid any type of accident. One can find several types of conveying systems such as hydraulic, mechanical, and fully automated systems. These systems can also be designed as per the customer's requirement.

Also Read: How RFID Technology Is Helpful to Conveyor Industry?

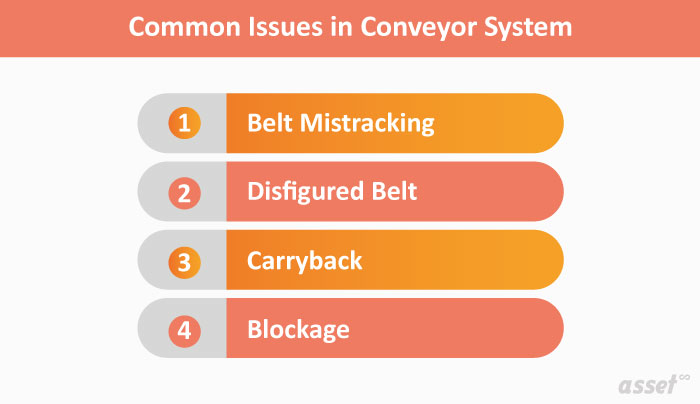

What Are the Common Issues That Occur in the Conveyor System?

The most common issues that occur in a conveyor system are as follow:

1. Belt Mistracking

This is the most common problem and if it is not handled properly then it can lead to other issues such as material spillage and rollers as well. Belt mistracking as you may get the idea from the name, the belt loses its track.

In clear words, the belt is not working as it should. It may have slipped from one side and due to which configuration of the machine is disturbed & adjustment needs to be done.

2. Disfigured Belt

The belt can be disfigured in many ways such as mistracking, over-weight, and so on. The belt is the most important and expensive part of a conveyor system. Therefore, it needs to be inspected closely & proactively so that its life expectancy is not compromised.

3. Carryback

Dust and small particles are always flying in the air. These small particles adhered to the surface of the conveyor belt and after time it gets accumulated inside & outside of a conveyor system.

If not serviced on time it can take the form of sicky clay and create problems. Even technicians have to struggle to eliminate them. These particles can degrade other parts of a conveyor system as well.

4. Blockage

Another common issue of conveyor system is blockage. Conveyor belt is the important part of system and purpose is to effectively travel of the material and if it get blocked that will cause a major issue.

What Precautions Can Be Taken to Avoid These Issues?

If you want a long working life for your conveyor system then maintenance must be given at a regular period so that severe breakdown can be avoided. However, these issues are recurring so conveyor maintenance is the most important part of the operation to keep your conveyor system optimized.

- Regular monitoring for conveyor system

- Don't exhaust machines to maximum capacity

- Track downtime for the conveyor system

- Replace the faulty piece of an equipment

Also Read: All You Need to Know About Preventive Maintenance Software

What Is Preventive Maintenance?

Preventive maintenance is a routine inspection of machines, equipment, and asset. It follows the simple philosophy “find all potential issues and resolve them as quickly as possible.”

Preventive maintenance is scheduled maintenance and it is proactive in mature. The goal of this maintenance is to avoid any type of asset failure.

This maintenance saves machines, assets from failure, and reduces asset downtime. As a result, productivity increases. Managers know when sudden equipment breakdown occurs then it leads to expensive maintenance and the bottom line is affected.

The benefit of preventive maintenance software is, it minimizes the chances of sudden breakdown and saved unnecessary maintenance expenses. Moreover, it increases the asset life.

In preventive maintenance oiling, cleaning, lubricating parts, changing wear and tear parts, filter changing, adjustment these types of activities are done! Most importantly inspecting equipment closely to find potential issues.

Preventive maintenance scheduling depends on several factors such as how frequently are you using, for how long the machine has been working continuously, and so on. Thus, it depends on your requirement.

How Preventive Maintenance Is Effective for Conveyor Problems?

In the event of failure occurrence, it will impact organization productivity badly. Your organization's production operations slow or might be stopped completely.

A conveyor system works continuously for several hours and if not maintained then chances are it will not work efficiently. However, if preventive maintenance is implemented then it will reduce the conveyor system failure probability and increase conveyor system life.

Moreover, you will know if any issue is coming in the conveyor system and provide you time to plan for overcoming the problem.

We have to remember that a machine breakdown occurs either sooner or later but the only question is “when”. And when it occurs, how will you handle the situation? It is simple! With proper maintenance.

Not a small issue shall be ignored, maintenance shall be done regularly, and by a professional team. By simple inspection of the conveyor system belt, surface, joints, etc. an organization can save a lot of money, precious time, and labor hard work as well.

Conclusion

Maintenance is the key to keep your conveyor system away from problems. If maintenance is not done on time it can cause asset failure, increase downtime, worker safety can be an issue.

Similarly, a conveyor belt can be diagnosed with belt mistracking, carryback, blockage, etc. Overall business productivity and efficiency will be affected. Therefore, preventive maintenance can be effective to avoid these scenarios.

Asset management software can also be effective. As it provides powerful features such as preventive maintenance and it is an effective tool used for asset management. This software has the potential to take your business to another level.

Also Read: Reactive Maintenance Vs Preventive Maintenance Vs Predictive Maintenance

Frequently Asked Questions (FAQs)

1. What is predictive maintenance?

Predictive maintenance is one of the best techniques for maintenance. It is also a type of proactive maintenance. It is used to track performance, monitor equipment conditions, and detect possible equipment issues. Eliminate problems before equipment failure occurrence. According to Statista, “It is expected that the global predictive maintenance market will reach around 23.5 billion U.S. dollars by 2024. The market is expected to grow at a compound annual growth rate of almost 40 percent between 2018 and 2024.”

2. Preventive maintenance and predictive maintenance, are they both the same?

Preventive maintenance and predictive maintenance are very similar to each other as they both are schedule maintenance proactive, find potential issues, and resolve them before asset breakdown. The only difference is predictive maintenance uses is condition based on the other hand, preventive maintenance time basis.

3. What are the different types of conveyor systems?

There are many types of conveyor systems are such as belt conveyors, roller conveyors, slat conveyors, over-under conveyors, vertical conveyors, inverted conveyors, and so on!

.png)