In order to keep your assets maintained you need to perform maintenance at regular maintenance. But the question is that there are so many types of maintenance are available. Some organizations rely on proactive maintenance, some prefer reactive maintenance! Which one to choose? Which one fits in your business?

In this blog, we are covering predictive maintenance, which will help you in and predictive maintenance suits your business or not! Without further ado let us begin!

What Is Predictive Maintenance?

Predictive maintenance is a type of proactive maintenance that consistently monitors asset conditions. It keeps track of asset performance with key performance indicators (KPI). Whenever performance shows a decreasing indicator then maintenance is scheduled to fix the issue.

Predictive maintenance ensures their equipment is provided maintenance before equipment failure can occur. For this purpose, data history is used, and proactive maintenance algorithms utilize.

According to Market Research Future, “The global predictive maintenance market is expected to expand at more than 25 percent CAGR to reach 23051 million in 2025 during the forecast period (2027)”.

Also Read: How Do Proactive Maintenance Solution Prevent Inefficiencies?

What Is the Objective of Predictive Maintenance?

The objective of predictive maintenance is to upgrade the utilization of your resources for maintenance. By knowing when a specific part will fizzle, the upkeep manager can plan maintenance work just when it is really required, all the while keeping away from exorbitant upkeep and forestalling sudden gear breakdown.

Other than this, objectives of predictive maintenance are given below:

- Keeping assets monitored to avoid sudden failure.

- Keeping equipment well maintained.

- Focus on increasing asset performance and keeping assets optimized.

- Prolonging asset life.

- Increase uptime and decrease downtime.

- Minimize upkeeping expenses.

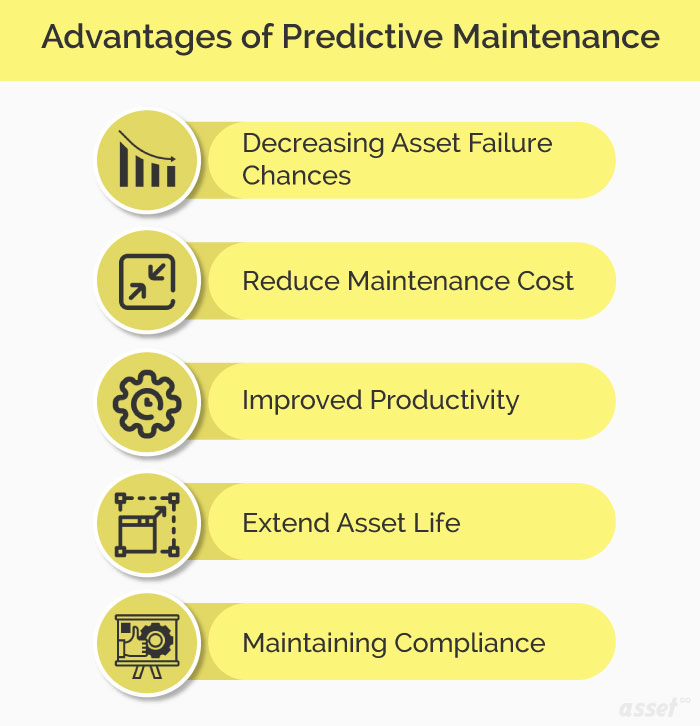

What Are the Advantages of Predictive Maintenance?

Advantages of predictive maintenance are discussed below:

1. Decreasing Asset Failure Chances

When machines are running continuously for a long time it is important that they get regular maintenance otherwise asset failure can occur which can be very dangerous for business. Predictive maintenance software ensures that equipment gets maintenance as you can set an alert for each piece of equipment.

2. Reduce Maintenance Cost

When you can predict failure and performance indicators are kept monitored. Then you can easily avoid sudden failure and make the asset more reliable. As a result, your maintenance is stabilized, and expenses are saved.

3. Improved Productivity

Predictive maintenance reduced time spent on maintenance keeps on decreasing. With predictive maintenance, the number of failures will decrease as well. The maintenance team can focus on enhancing asset performance.

Moreover, with predictive maintenance software, you do not have to worry about maintenance scheduling and the maintenance team gets a checklist for each work order.

So that they already know what activities need to be done. So, it increases productivity.

Also Read: What Are the 5 Key Stages of Asset Life Cycle Management?

4. Extend Asset Life

When you utilize predictive maintenance it minimizes maintenance expenses, improves performance, and increases uptime. Most importantly it increases asset life.

Predictive maintenance software monitors the condition of each asset and keeps track of it. Providing maintenance on time and monitoring & managing them properly will result in extended asset life.

5. Maintaining Compliance

Lots of organizations pay huge amounts of penalties due to violations of compliance rules. It is mandatory for organizations to follow rules and regulations as per their industry basis otherwise your organization will be penalized.

Due to unmaintained assets, several organizations end up paying penalties. But with predictive maintenance software, you can ensure that assets are maintained, and rule violation occurs especially related to worker safety, asset safety, and asset maintenance.

What Are the Best Practices of Predictive Maintenance Software?

Best practices of predictive maintenance software are discussed below:

1. Categorize Assets

It is a very important part of maintaining assets that managers identify assets that are critical and non-critical. So that while planning maintenance you can decide on a priority basis which assets shall be given maintenance first!

It is an essential practice for the maintenance team so that their time is saved by not working on non-critical assets.

2. Utilize Asset Tracking Technique

Asset tracking techniques can play a crucial role in asset maintenance. Moreover, they provide crucial data that is helpful in analyzing performance. Furthermore, it keeps track of assets as well as saving from theft and misplacement.

Asset tracking techniques are several such as barcode, QR Code, RFID, etc. These technologies come in the form of tags. One tag is attached to all assets that need to be tracked. With this technique, you can get real-time information as well.

3. Identify Pitfalls

It is crucial to figure out what is the main issue and how it is hindering the productivity of the organization. With data, you can identify several problems and once you figure it out things will be simplified, and business will grow at tremendous speed.

With automated software, you can get fetial reports through which identifying problems become simple and you can tackle them easily.

Conclusion

Predictive maintenance is significant, however, requirements may vary from one organization to another as this maintenance strategy might not suit as per their requirement.

It is important that you know in advance what you are looking for then only you can find the best maintenance software such as computerized maintenance management system (CMMS) software or predictive maintenance software.

There is no doubt that predictive maintenance has a lot of potentials to minimize the maintenance expenses and it streamlines the maintenance process as well.

Also Read: A Simplified Approach to Asset Maintenance Software

Frequently Asked Questions (FAQs)

1. Why is predictive maintenance software important?

Predictive maintenance software is important because it assists an organization in several ways such as reducing labor work, safety compliance, repairing and setting alignment right improving the efficiency of assets, decreasing overall maintenance expenses, and so on.

2. What are the different categories of maintenance?

Maintenance can be categorized into two categories proactive maintenance and reactive maintenance. Preventive maintenance falls into the proactive maintenance category other than this predictive maintenance and condition monitoring maintenance are also in the same category. Whereas in reactive maintenance there is emergency maintenance, breakdown maintenance, and Run-to-failure maintenance, etc.

3. What are the benefits of CMMS software?

CMMS software provides several other benefits that we have given below:

1. Scheduling maintenance

2. Maintenance tracking

3. Asset maintenance history

4. Purchase order creation and tracking

5. Ensure compliance & safety regulation

6. Work order creation and tracking

7. Centralized system

8. Reports and statistics

.webp)

.jpg)

.jpg)