Assets are changing and updating with time. Machines are becoming more important for running a business and their price is also growing regularly. That is why you cannot just used asset and throw away & this is where equipment and asset need maintenance.

Organizations must keep assets well-maintained and in good shape and condition. But organizations have hundreds or thousands of assets but keeping all of them maintained is a huge task!

In this blog, we will know how you can maintain assets in abundance! What are the different types of maintenance strategies & which maintenance strategy fits into your business! So, let us begin!

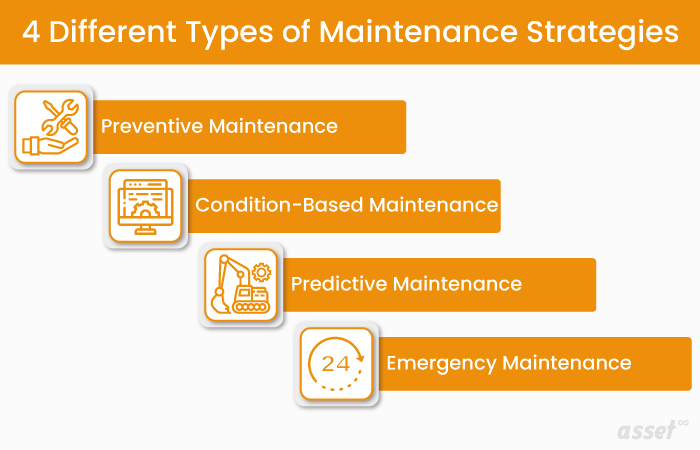

How Many Different Types of Maintenance Strategies Are There?

There are many different types of maintenance strategies that we have discussed below:

Also Read: What Are the Top Features of Maintenance Management Software?

1. Preventive Maintenance

Without any doubt, preventive maintenance is a significant component of the maintenance procedure. It is a vital aspect for minimizing maintenance costs as well as minimizing downtime.

It can also help in creating a safe environment for employees, asset life expectancy, and also their productivity. A decent preventive upkeep plan includes keeping records of inspection, maintenance.

Preventive upkeep alludes to routine & regular, scheduled maintenance to assist equipment running, forestalling any asset failure (expected or unexpected). Preventive maintenance can be scheduled on a timely basis or usage-based.

Timely-Based Maintenance - A maintenance that is scheduled as per the time such as daily, weekly, monthly, etc.

Usage-Based Maintenance - A maintenance that is scheduled as per the usage of equipment. For instance, a vehicle needs to be maintained after 1000-km of usage.

2. Condition-Based Maintenance

In condition-based maintenance, the guesswork needs to be done. In this calculated risk is taken and just like preventive maintenance usage of equipment and how frequently machine is used.

Furthermore, previous data is also used. A detailed inspection of the machine is done & checked in all prospects. Maintenance is only done when assets need to be maintained.

In some cases, condition-based maintenance is more effective than preventive and predictive maintenance. In this maintenance strategy, only those parts are changed that are about to fail so unnecessary expenses are saved.

It needs a maintenance technician that is highly skilled and has a good understanding of machines and equipment so that calculated risk is as precise as it can be.

3. Predictive Maintenance

Predictive maintenance monitors assets and to detects a sign of asset failure or any type of issue. So that you can utilize assets and avoid asset failure before they occur. This is one of the cost-effective maintenance techniques.

One of the biggest challenges in predictive maintenance that it requires a highly skilled and knowledgeable maintenance technician. So that he can use data and analytics for a better understanding of the asset.

Also Read: What Are the Pros and Cons of Corrective Maintenance?

According to Statista, “The distribution of scheduled maintenance in the manufacturing industry worldwide in 2017. As of that time, 34 percent of the respondents reported spending 30 hours or more in plant maintenance.”

Predictive maintenance enhances the asset life, productivity and minimizes breakdown chances of asset, and increases the return on investment (ROI). In the long run, you will notice maintenance expenses are decreased.

4. Emergency Maintenance

Organizations that do not have any plans utilizes emergency maintenance. In this maintenance, critical assets are given maintenance after they are broken.

Emergency maintenance is a reactive maintenance type. It is a maintenance type that can be expensive depending on asset failure.

Emergency maintenance is also known as breakdown maintenance. When sudden asset failure occurs then emergency maintenance is utilized. When a sudden breakdown occurs, it leads to a work halt and employee productivity suffers.

Emergency maintenance can be a consequence of run-to-failure or sudden asset failure (reactive or unexpected asset failure). No planning or scheduling of maintenance is done in advance, no warning either that is sudden asset failure.

Sudden failure (unexpected failure) of critical assets is usually expensive. However, assets need to be bought back into running condition as soon as possible.

On the other hand, run-to-failure maintenance is done by choice. It means it is planned when a breakdown will occur the team is there on standby to resolve an issue with all inventories available. This type of maintenance is utilized on non-critical assets.

Conclusion

The best maintenance strategy is that in which organizations do not rely on just a single maintenance strategy. There must be types of maintenance strategies in business for more efficient work.

For instance, every organization has critical assets and non-critical assets for critical assets one can utilize proactive or condition-based maintenance and for non-critical assets, organizations can utilize reactive maintenance.

When you will utilize more than one maintenance types you can compare price, performance, and other criteria.

Organizations need to divide assets into 2 categories critical assets and non-critical assets. But how to do that?

As we said at the beginning of the blog that how will one manage when they have assets in abundance?

The answer to both questions is the same, Maintenance Management Software. This software will not only help in keeping track of assets but will also assist in scheduling maintenance. Furthermore, you can easily categorize your assets.

CMMS plays a crucial role in maintaining assets in good condition. This software offers data and analytics that helps maintenance manager in understanding the equipment and equipment's performance.

Asset history lets you know how much maintenance an asset is taking and how asset performance can be improved!

Speaking of asset performance, the data of CMMS software can assist in improving asset performance. It might be hectic in the beginning especially for those organizations which are shifting from pen-paper to automated software utilization. But in the long run, CMMS software benefits are enormous.

At last, every organization has a unique requirement therefore team needs to figure out which maintenance strategy will be more effective in their operation & routine.

Every organization wants to maximize equipment life and performance and decrease breakdown chances. CMMS can help you in achieving that.

Also Read: What Are the Objectives & Functions of Maintenance Management?

Frequently Asked Questions (FAQs)

1. How predictive maintenance is different from preventive maintenance?

The only difference between them is predictive maintenance only shuts down assets when asset breakdown about to happen. Therefore, assets and resources are more utilized compared to preventive maintenance.

2. What are the benefits of CMMS Software?

The benefits of CMMS software are as follow:

Maintenance scheduling, increasing asset life expectancy, decreasing downtime, increasing uptime & availability of assets, controlling maintenance expenses, track maintenance history, asset optimization, informed decision making.

3. What are the disadvantages of preventive maintenance?

The disadvantages of preventive maintenance are that it is costly, planning is required, staff and resources are required in advance.

.webp)

.jpg)

.jpg)