The main objective of equipment maintenance is to reduce the probability of breakdown & maximizing the efficiency of equipment functionality. The maintenance of equipment is very crucial in minimizing cost. For every organization, business equipment maintenance is mandatory to grow your business.

Let us discuss in detail all the aspects of equipment maintenance. So, let's begin!

What is equipment maintenance?

Equipment maintenance does not mean repair when it is not working. It is a regular practice for keeping your equipment maintained.

As a professional practice, one should keep an emphasis on maintenance rather than repairment. In simple words, to keep your equipment in good working condition, routine maintenance should be done on a regular basis.

Equipment may incorporate mechanical assets, computers, laptops, excavators, cranes, bulldozers. The assets expected to be kept in good shape always.

Because repair varies from size & time. For example, if a crane is repaired it may consume much more time compared to a laptop. A crane is a piece of big equipment and it may take a lot of time to figure out the issue.

Why equipment maintenance is important?

When equipment is in good condition it will perform better and productivity increases. It is responsible for running a smooth operation. Also, it will save from an unexpected breakdown.

However, you may need a separate team to look out for these activities and how they will maintain the equipment? With the assistance of Asset management software, it provides all the information about an equipment or asset.

It also keeps records of each asset, for instance, it can inform you when was the last maintenance done. When it needs the next maintenance. You can schedule maintenance activities without interrupting daily work.

Also Read: Paper Based Preventive Maintenance can be critical for your business

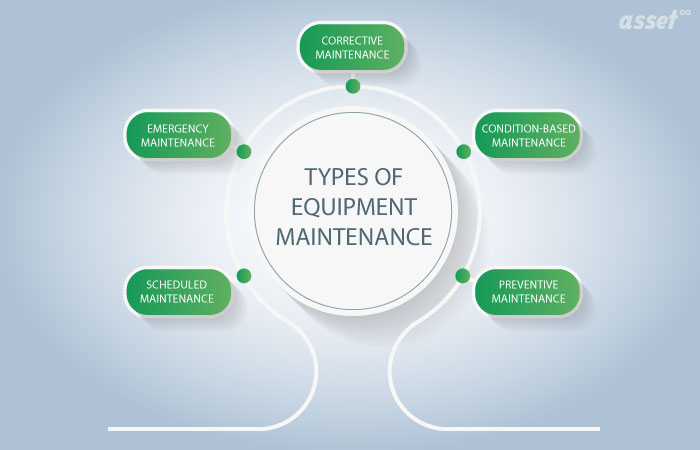

What are the types of equipment maintenance?

There are several types of equipment maintenance, but it depends on what type of maintenance your organization requires?

What is the size of an organization?

Here is an example If your organization is small-sized then you may go for reactive maintenance but if your organization is a big size company then you may choose preventive maintenance. So, every organization has a different maintenance need.

Types of equipment maintenance can be divided into two parts planned maintenance and unplanned maintenance. It includes the below features.

Corrective maintenance

When any defect or fault is found in the equipment then corrective maintenance is implemented. The aim of this activity is to make the equipment work fine. Also, its functionality should be working fine after this maintenance activity. Corrective maintenance can be a planned or unplanned activity.

Condition-based maintenance

It does not depend upon the technology to determine the condition of the equipment. This approach is not reliable. It works on human-based skills. For example, a manager will give a task to an operator to monitor the equipment to look at the condition of the equipment. However, to perform this type of task operator should be skilled, highly trained and experienced.

Preventive maintenance

This is the most popular and used practice in maintenance activity. This is part of planned maintenance. Its main focus is to avoid any problem that can cause problems in the future. Preventing the potential problem is the objective of this preventive maintenance activity. For this, Equipment maintenance software can be used to detect any potential issues.

Scheduled maintenance

At the month's end or after 45 days or after a certain period of time in an organization a maintenance activity takes place that is known as scheduled maintenance. This activity is part of the planned maintenance activity. It is effective as these are scheduled in advance.

Emergency maintenance

As the name suggests, this activity is unplanned and unscheduled. When a piece of equipment needs immediate attention in order to keep the equipment safe, operational or productive that is emergency maintenance. It affects the other activity of the organization. Plus, it is a very costly maintenance.

Other than this, there are few lesser-known maintenance practices such as deferred maintenance, total productive maintenance, predetermined maintenance.

Also Read: 7 Aspects You Must Look While Choosing Asset Management Software

What are the industries that use equipment maintenance & What are the examples?

Equipment is there in almost every Industry. But here are the few industries that have equipment that is the backbone of their Industry.

Construction Industry

The construction industry has huge equipment such as excavators, backhoe, dragline excavators, bulldozers, etc. They are used in a big project for different-different purposes. This equipment is quick and effective, but they need maintenance at regular intervals.

Transportation Industry

Transportation industry sends the goods from one place to another for the purpose of business or any other reason. Transporting can be done via Ships, Rails, Trucks, etc.

Manufacturing Industry

After that, the manufacturing industry is related to all the industries combined it manufactures the automobile parts, electronic goods, pharmaceuticals, etc. Plus, combining all these industries together.

Why preventive maintenance considered most crucial?

It is considered most crucial because by performing it at regular intervals it operates under the safe condition. This activity creates a risk-free environment for employees and machines. It avoids uncertainty factor & equipment failure.

Also, it plays an important role in predicting future issues. Not just that it also optimizes the equipment performance for better output. It saves lots of money & increases equipment lifespan.

What are the advantages of Equipment Maintenance?

Equipment runs efficiently

When equipment maintenance is done on time then equipment runs efficiently. When equipment runs efficiently then business runs smoothly. As a result, the project is done on time or before the deadline. Because, if the maintenance suffers so is does the productivity.

Identify the potential problem

What if we keep avoiding the small issues in equipment? Someday in the future, it will become a daunting task. Hence every issue must be resolved as soon as possible, and every problem must be addressed in order to run the organization smoothly. Because, if it's not done on time it can burn a hole in your pocket.

Increased lifespan & resale value

In business, everybody has to stay updated. So, when an updated version is launched to specific equipment, chances are you will also try to sell your old equipment for the new one. Therefore, one must perform the maintenance activity to get the maximum resale value.

Also Read: What Are the Various Stages of the Fixed Asset Life Cycle?

Conclusion

The equipment is made of iron, especially big ones. They can catch dirt. This big equipment is made up of several parts joint together.

Hence, they can get moisture and rust in the rainy season. So, keeping them clean and maintained is really important for equipment maintenance. Otherwise, we know can be the consequences, a costly repair. To save & extend equipment life one should definitely do equipment maintenance.